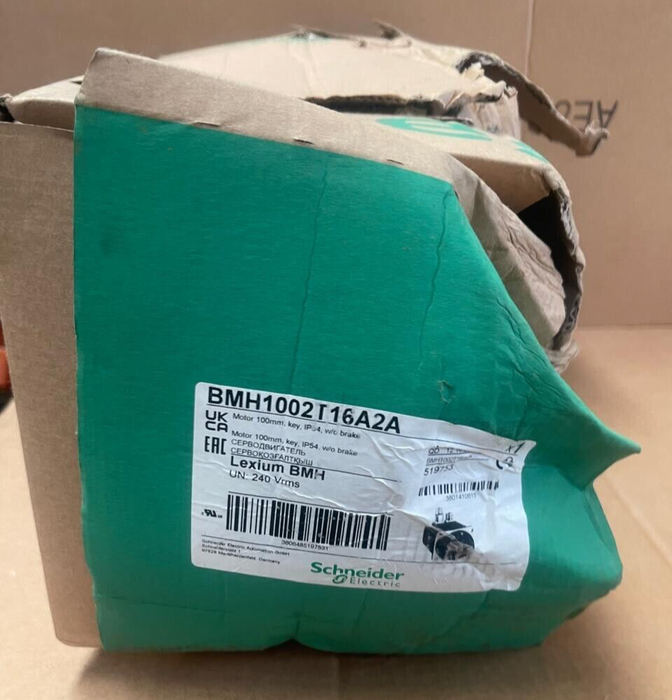

Schneider Electric – BMH1002T16A2A – Lexium 32 Servo Motor

The Schneider Electric BMH1002T16A2A is a high-performance servo motor from the Lexium 32 range, engineered to deliver precise motion control in industrial automation applications. This 10-pole synchronous servo motor offers a continuous stall torque of 6 Nm and can achieve speeds up to 6000 rpm, making it ideal for dynamic and accurate operations. It features a keyed shaft without a holding brake and is equipped with a 16-bit single-turn SinCos encoder, ensuring high-resolution position feedback. The motor is designed for natural convection cooling and has an IP54 protection rating, providing resistance against dust and splashing water, which enhances its reliability in various industrial environments.

Key Features:

• High Torque and Speed: Delivers a continuous stall torque of 6 Nm and operates at speeds up to 6000 rpm, suitable for demanding applications.

• Precision Feedback: Equipped with a 16-bit single-turn SinCos encoder for accurate position monitoring and control.

• Robust Construction: IP54-rated enclosure ensures protection against dust and water splashes, enhancing durability in industrial settings.

• Flexible Integration: Features a keyed shaft design without a holding brake, allowing for versatile installation in various systems.

• Efficient Cooling: Designed for natural convection cooling, eliminating the need for external cooling systems.

Technical Specifications:

• Model Number: BMH1002T16A2A

• Continuous Stall Torque: 6 Nm

• Maximum Speed: 6000 rpm

• Rated Power: 1.45 kW

• Rated Voltage: 240 V AC

• Continuous Stall Current: 8.65 A

• Encoder Type: 16-bit single-turn SinCos

• Shaft Type: Keyed, without holding brake

• Protection Rating: IP54

• Cooling Method: Natural convection

• Certifications: [Information not specified]

Applications:

• Industrial Automation: Ideal for precise control in manufacturing processes, such as CNC machinery and robotics.

• Material Handling: Suitable for conveyor systems requiring accurate speed and position control.

• Packaging Equipment: Ensures synchronized movements in packaging lines for improved efficiency.

• Textile Machinery: Provides reliable performance in high-speed textile production equipment.